How are businesses plotting a path to net zero?

Read our selection of net zero case studies, from industries across the UK and Europe to see how businesses like yours are reducing emissions and moving closer to their net zero goals.

Read our essential guide to net zero funding to find out more about how npower Business Solutions explores renewable funding opportunities and green energy grants to help your business take its next steps towards net zero.

Read our Case Studies

A lack of public charging facilities is often cited as a perceived barrier by drivers considering swapping to an electric vehicle. But thanks to a project being overseen by E.ON Solutions for Network Rail, almost 450 fast chargers are now available at some of the UK’s busiest railway stations.

And a further 400 are due to be installed over the coming months. “The fast-charging, 3 Phase 22kW AC units are already live at Leeds, Manchester Piccadilly and Reading stations, and are being extended to Edinburgh Waverley, Welwyn Garden City and Birmingham New Street,” explains Richard Spencer, Head of Technical Services & Operations at E.ON. “The project will provide a total of 833 EV chargers on completion.”

“The fast-charging, 3 Phase 22kW AC units are already live at Leeds, Manchester Piccadilly and Reading stations, and are being extended to Edinburgh Waverley, Welwyn Garden City and Birmingham New Street,”

Richard Spencer,

Head of Technical Services & Operations

Working with technology provider Compleo Charging Solutions UK, the newly-installed charging network enables visitors to Network Rail car parks to take advantage of a bespoke parking solution that combines their parking and EV charging costs within a single fee. This has also been integrated into carpark operator APCOA’s ‘Connect’ App, enabling easy payment and charging authentication from any smart phone.

“As part of our wider Environmental Sustainability Strategy, we’re working towards delivering a low-emission railway, and supporting the move to electric and ultra-low emissions vehicles is a key part of that,” says Jo Lewington, Network Rail’s Chief Environment & Sustainability Officer.

“We hope that by providing affordable, efficient and reliable charging points, we can encourage more electric vehicles onto the road and help promote healthier air in and around our stations.”

The EV charging project for Network Rail is one of many being managed by E.ON across the UK.

As one of the UK’s largest and best-known retailers, Tesco manages a huge portfolio of almost 3400 stores and petrol stations.

With such a large estate, it’s no wonder Tesco has long been prioritising energy efficiency, and has worked with E.ON for more than 13 years to implement large-scale, multi-site energy-management projects.

Now that Tesco has committed to a science-based strategy to become a carbon neutral business by 2050, E.ON is continuing to support with solutions that provide energy tracking, monitoring and data insight functionality.

“More than 2,900 Tesco stores are now connected to our 24/7/365 Energy Management Centre (EMC) to monitor energy use and operations,”

Gordon Cameron,

Head of EMC at E.ON Control Solutions.

“More than 2,900 Tesco stores are now connected to our 24/7/365 Energy Management Centre (EMC) to monitor energy use and operations,” explains Gordon Cameron, Head of EMC at E.ON Control Solutions.

“This provides Tesco with energy dashboards with a breadth of information across their estate to enable them to drill down and look at detailed consumption data at site level. We then work with them to help prioritise actions, identify inefficiencies and target wastage, preform remote fixes and implement changes, and track results and financial returns from what the data is telling us.

“We also work closely with the Tesco maintenance teams to support energy and store improvements while maintaining a comfortable store environment for shoppers. And we carry out real-time tracking for carbon-saving projects such as store re-engineering.” Working in partnership with E.ON Control Solution to manage energy costs and prioritise proactive maintenance has enabled Tesco to achieve 50% of their annual energy reduction via remote connectivity initiatives and maintenance in the last financial year. “What sets Tesco apart is their understanding of the value of energy data – and also putting these findings into actionable decisions and projects,” says Gordon. “This level of control gives complete visibility of the health of their vast estate and associated energy consumption profiles, and helps support their net zero goals by helping them optimise and reduce energy use.”

Providing fast-chargers for EV drivers at UK railway stations

Harnessing biomass to heat Yorkshire businesses

Blackburn Meadows is an E.ON owned and operated biomass-fueled combined heat and power (CHP) plant in Sheffield. It provides heat and power for up to 69,000 homes and businesses in South Yorkshire, but with 65% fewer carbon emissions compared to the use of natural gas.

Every year, it converts 200,000 tonnes of UK-sourced waste wood that would otherwise go to landfill, into 30MW of electrical energy and up to 25MW of thermal energy. The wood is burnt to create steam which generates electrical energy that goes onto the grid. The plant also supplies heating through E.ON’s own district heating network to local businesses including IKEA UK, Forgemasters, Sheffield Arena and Ice Sheffield.

“Connecting to the Blackburn Meadows biomass plant has meant a reduction in our emissions of over 700 tonnes of CO₂, which supports our environmental credentials while also helping decarbonise Sheffield.”

Gordon Cameron,

Head of EMC at E.ON Control Solutions.

According to the Environmental Team at Forgemasters: “Connecting to the Blackburn Meadows biomass plant has meant a reduction in our emissions of over 700 tonnes of CO₂, which supports our environmental credentials while also helping decarbonise Sheffield.”

E.On has also installed a 10MW battery at the Blackburn Meadows site to participate in ‘enhanced frequency response’ services to support National Grid to manage fluctuations in the UK electricity network. This battery storage system has the capability to respond to calls to discharge energy to the grid in less than one second, providing a cleaner, more responsive solution to help National Grid balance the growing volume of intermittent renewable generation.

Supporting Tesco’s net zero goals

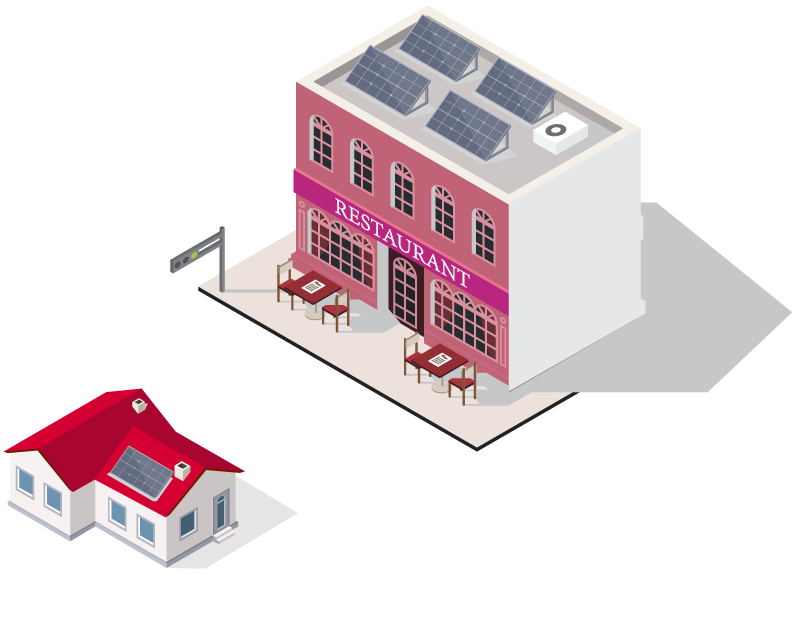

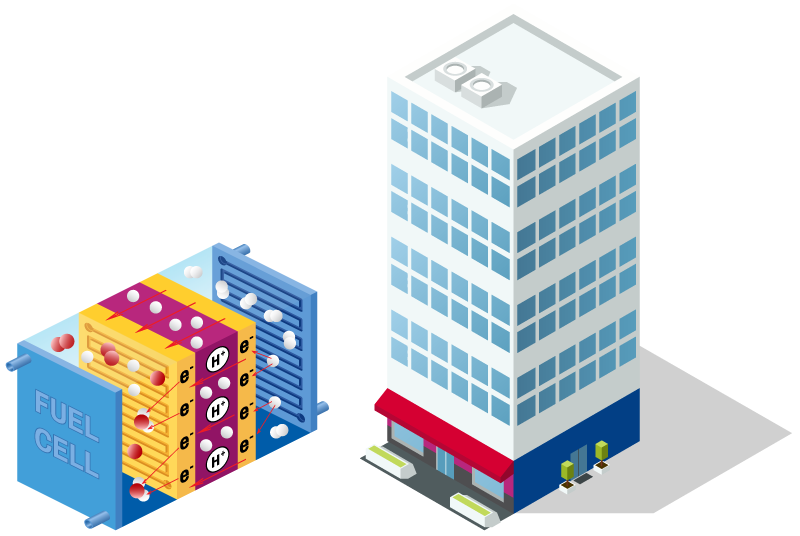

The Radisson Hotel Group (RHG) is one of the world’s leading hotel brands with nearly 300 hotels across 69 countries and territories. Thanks to an innovative project in partnership with E.ON, the group’s Radisson Blu Hotel in Frankfurt, Germany, became the first hotel in Europe to have power and heat supplied by industrial-size fuel-cell technology.

Since the summer of 2017, hydrogen-powered fuel cells operated by E.ON have provided approximately 3GWh of electricity and 2GWh of heat to the hotel.

“The effects of the technology – plus the subsidy from combined- heat-and-power legislation – created energy cost savings of approximately €60,000 in the first year. Assured total savings amount up to around €750,000 over the contract time of 10 Years.”

RHG

This has reduced the hotel’s CO2 emissions by about 600 tonnes a year.

This innovative technology is environmentally friendly, proven and fully operational – having already been employed in the United States for a number of years. The fuel cells are located outside the hotel, with electricity and heat transferred by cable and pipeline to the hotel’s distribution network in its basement.According to RHG: “The effects of the technology – plus the subsidy from combined-heat-and-power legislation – created energy cost savings of approximately €60,000 in the first year. Assured total savings amount up to around €750,000 over the contract time of 10 Years.”

Harnessing biomass to heat Yorkshire businesses

Award-winning project delivers carbon saving and revenue for council

Like all local authorities, West Sussex County Council (WSCC) is under pressure to reduce carbon emissions. But due to an ambitious 2030 net zero target, it’s having to move faster than most.

Now, thanks to an innovative solar and battery storage project developed in partnership with npower Business Solutions, it’s found a way to both cut emissions and generate income. And in June 2021, the project won a Special Award for Contribution to Net Zero(Highly Commended) in the Association of Decentralised Energy (ADE) Awards.

“Through this innovative, flexible approach, we have seen WSCC achieve significant success against its sustainability and financial objectives for the site,”

Dan Jerwood,

Demand Side Response Manager at nBS

The project, located on disused landfill site at Westhampnett near Chichester, became the UK’s first subsidy-free solar farm operated by a local authority when it became fully operational in January 2019. A 7.4MW solar photovoltaic (PV) array sits alongside a co-located large-scale lithium-ion battery, which allows the power generated to be commercially optimised.

In partnership with LASER, a public sector buying group, nBS worked closely with WSCC upfront to gain a comprehensive technical and commercial understanding of the council’s challenges and ambitions for the site.

This included: Sale of power and embedded benefits via a PPA Access to DSR including Firm Frequency Response (both Static and Dynamic) and Capacity Market participation, plus Triad export benefit (until March 2023) Price arbitrage and targeted activity in wholesale markets “Through this innovative, flexible approach, we have seen WSCC achieve significant success against its sustainability and financial objectives for the site,” says Dan Jerwood, Demand Side Response Manager at nBS.

Daire Casey, Energy Services Manager at WSCC at the time of project, adds: “A report we commissioned from independent consultants Cornwall Insight provided a glowing overview of the optimisation strategy and overall performance against the market. Of particular interest was the conclusion that once the battery was fully up and running in the second half of the year, it secured the second largest weighted average Firm Frequency Response price for that period compared to similar assets in the market.”

Supporting Radisson to achieve a Europe-first for fuel cell technology

Historic sea port city moves closer to net zero goals

Like many local authorities, Southampton City Council (SCC) has set itself an ambitious target of achieving net zero emissions by 2030.

Now thanks to a programme of work recently completed by the team at E.ON Control Solutions, working on behalf of SCC supplier and sister organisation npower Business Solutions (nBS), the historic waterside city has taken some significant steps closer to its goal. So if you happen to visit the city’s Lordshill Library, you may notice new double-glazed windows reducing heat loss and noise, or LED lighting providing improved illumination at nearly half the cost of the previous inefficient fluorescent lighting.

“All these improvements have only been in place for about three months now, but our initial calculations suggest they will collectively reduce our CO2 emissions by a minimum of 150 tonnes each year and save us £140k worth of energy at 2019 prices, which is significantly more today as prices have since doubled.”

Jason Taylor,

SCC Energy Manager

Solar PV panels now adorn the roof of flagship council building One Guildhall Square. As they do at the city’s main household waste and recycling centre, City Depot, where a new air source heat pump and LED lighting further support significant cost and carbon savings. Behind the scenes in various public buildings– including the Sea City Museum, which tells the story of the Titanic – modified air handling units are increasing efficiencies and reducing maintenance bills. Variable speed drive technologies are also cutting costs and emissions by enabling operations such as air conditioning to be tailored to occupancy.

“All these improvements have only been in place for about three months now, but our initial calculations suggest they will collectively reduce our CO2 emissions by a minimum of 150 tonnes each year and save us £140k worth of energy at 2019 prices, which is significantly more today as prices have since doubled,” says SCC Energy Manager Jason Taylor.

Award-winning project delivers carbon saving and revenue for council

Generating renewable power to make the UK’s favourite crisps

Like many consumer brands, Walkers – makers of the UK’s favourite crisps – is keen to embrace more sustainable business practices. And as part of the PepsiCo group, it is working towards becoming net zero by 2040.

While a range of initiatives to bring Walkers closer this goal have been instigated in the past few years, it first adopted onsite renewable generation back in 2015. A team from npower Business Solutions (nBS) designed, secured planning permission and installed a 2,300kW [X-size] wind turbine at Walker’s manufacturing plant in Skelmersdale, West Lancashire.

Under the terms of the ‘Build, Own, Operate and Transfer’ (BOOT) [what type – PPA?] deal, nBS operate the turbine and supply the carbon-free power to Walkers for a 20-year period.

The project was delivered on time, under budget and with a 100% health and safety record by the time it became operational in December 2015.

Under the terms of the ‘Build, Own, Operate and Transfer’ (BOOT) [what type – PPA?] deal, nBS operate the turbine and supply the carbon-free power to Walkers for a 20-year period.

Generation averages 4,520 MWh per year, saving around 2000 tonnes of carbon – all from just one wind turbine. What’s more, at today’s wholesale market costs, this equates to approximately £1.3m* in annual savings.

*Based on a price of 30p per kilowatt hour

Historic sea port city moves closer to net zero goals

German printer optimises energy use with waste heat solution

Thanks to a waste heat solution installed by E.ON and its partner Orcan Energy, Mohn Media is now able to convert unused heat at its Gütersloh-based printing plant into almost 500,000 kilowatt hours of electricity each year – and offset around 300 tonnes of carbon emissions in the process.

This CO2-free energy also improves the energy efficiency of the printer which, as part of the Bertelsmann Printing Group, produces catalogues, brochures, books and magazines for European clients.

“We see responsible action as the basis for our economic success. With the help of these waste heat solutions, we have succeeded in further optimising the use of energy in our company.”

Ralf Niediek,

Head of the energy centre at Mohn Media

The new energy source is produced by utilising Organic Rankine Cycle (ORC) technology to harness waste heat from Mohn Media’s existing Combined Heat & Power (CHP) plant.

“ORC works like a mini steam power plant, except we use a low-boiling-point organic liquid instead of water,” explains Dr Edward Mitchell, a UK-based project engineer with E.ON Solutions. “This means we can generate electricity from lower-temperature heat sources. So it’s a fantastic option for businesses that generate a lot of heat in their day-to-day activities – such as glass, cement and smelting industries – as well as things like flues from CHPs.”

“Our focus has long been on using energy sparingly and effectively,” says Ralf Niediek, Head of the energy centre at Mohn Media.

“We see responsible action as the basis for our economic success. With the help of these waste heat solutions, we have succeeded in further optimising the use of energy in our company.”

Waste heat solutions can be an important component of a business’s sustainability journey. “We can now help industrial and business customers like Mohn Media on an even broader basis to reduce their energy costs and decarbonise their business,” says Dr Alexander Fenzl, head of E.ON Business Solutions in Germany.

From planning to installation, financing to operation and maintenance of the system, E.ON can take care of the energy supply as a complete, tailor-made package.

Generating renewable power to make the UK’s favourite crisps

Providing award-winning sustainable heat for the City of London

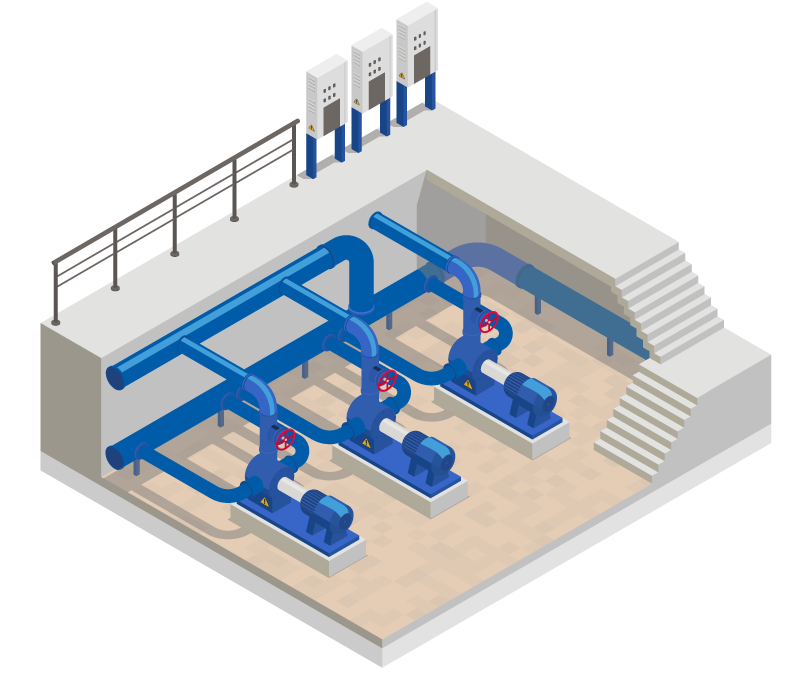

Citigen is one of the UK’s largest decentralised energy networks, providing low-carbon heating and cooling to City of London and the 8,000 people who live there, plus the approximate 480,000 commuters who travel there daily for work.

Operated by E.ON since 1992, this hidden tri-generation power plant sits below the streets of London’s square mile, and uses internal combustion engines to provide 35,000MWh of heat, 10,000MWh of cooling and 11,000MWh of electricity to the city’s homes and businesses.

Now thanks to a 4MW heat pump – which is around 1,000 times larger than the average heat pump for a typical UK home – Citigen’s carbon emissions will be further reduced by around 30%.

“The challenges we face in a place like the city are particularly high. We’ve got ever-increasing energy demands and the need to supply energy ever-more efficiently with lower carbon emissions. One answer to this is setting up schemes like Citigen with E.ON, with whom we have a long-term development agreement.”

Andrew Crafter

of the City of London Corporation

“We have an ambitious sustainability agenda and seek to reduce our carbon emissions to zero,” says Andrew Crafter of the City of London Corporation. “The challenges we face in a place like the city are particularly high. We’ve got ever-increasing energy demands and the need to supply energy ever-more efficiently with lower carbon emissions. One answer to this is setting up schemes like Citigen with E.ON, with whom we have a long-term development agreement.”

The new heat pump will draw natural warmth from the London Aquifer – which is a body of groundwater with an average temperature of 14°C sitting in the chalk basin below London – via three 200m boreholes. It will also utilise recycled waste heat from power and chill generation, which would otherwise vent into the atmosphere.

This zero-carbon heat pump will be equal to the demand of 2,300 UK homes or businesses. This is complemented by a further 2.8MW of new cooling capacity for customers across the business district.

At the recent 2022 UK Real Estate Investment and Infrastructure Forum awards, Citigen won the Infrastructure Project of the Year for the new heat pump installation. “The judges praised the project’s winning strengths of sustainability, lowering carbon emissions, embracing innovation and focusing on social value,” says Paul Healy, Head of E.ON Business Solutions. “Working collaboratively, we’ve built a lasting legacy by decarbonising the City of London through the electrification of heat.”

/npm214%20Digital_H_UB145.jpg)